Xioneer VXL Soluble Support Material

Soluble Support Materials

for Miraculous 3D Prints

Our unique support materials VXL 70, VXL 90, VXL 111, and VXL 130 print effortlessly, adhere to most model materials, and dissolve quickly.

VXL Soluble Support Materials

Compatible With Advanced

Model Materials

VXL support material has excellent adhesion to most thermoplastic materials. It bonds to PETG, ABS, TPU, PC, PA, and many other 3D printing materials like a strong glue.

Check compatibility:

VXL Soluble Support Materials

Compatible With Advanced

Model Materials

VXL support material has excellent adhesion to most thermoplastic materials. It bonds to PETG, ABS, TPU, PC, PA, and many other 3D printing materials like a strong glue.

VXL Soluble Support Materials

Exceptional

Thermal Performance

Unlike PVA or BVOH, our support material does not degrade in your nozzle even after prolonged exposure to heat. It is also less sensitive to air moisture, making VXL probably the most reliable support material you can find.

Compare VXL with PVA:

VXL Soluble Support Materials

Exceptional

Thermal Performance

Choose your VXL

We have created 4 different soluble support materials –

each with unique characteristics and temperature resistance.

Model Materials

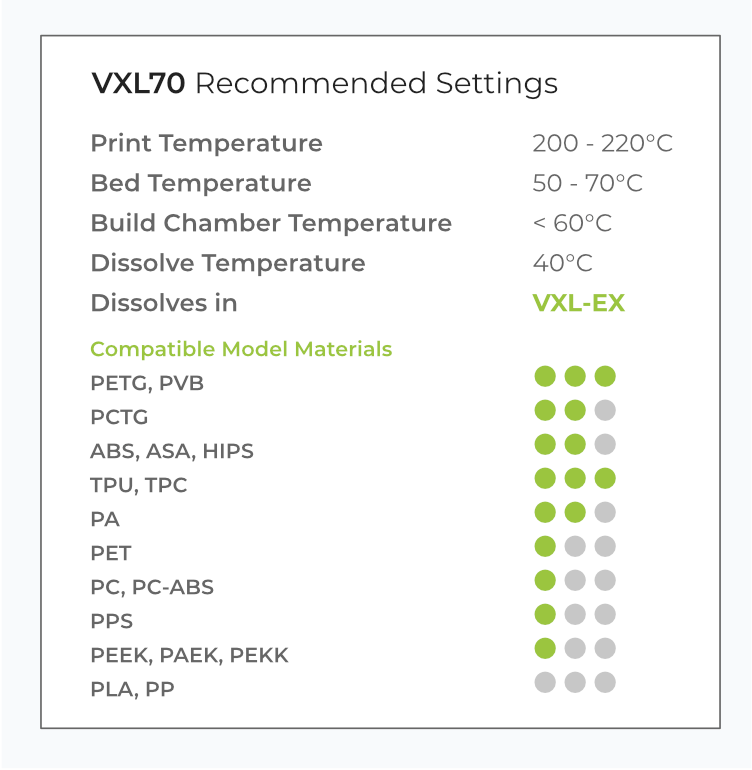

| VXL 70 | VXL 90 | VXL 111 | VXL 130 | |

| Extruder | 200 - 220 °C | 220 - 240 °C | 230 - 250 °C | 260 - 280 °C |

| BedBed temperature is especially dependent on the used substrate. Use top end temperature on PEI sheet. | 50 - 70°C | 70 - 90 °C | 90 - 110 °C | 100 - 130 °C |

| Build ChamberThese temperatures are slightly below softening point of our materials. The closer you get, the more you need to cool the filament feed path. | Up to 60 °C | Up to 80 °C | Up to 100 °C | Up to 120 °C |

| DissolutionLower temperatures will work, but increase dissolution time. Take care not to damage your model by too much heat! | Min 40 °C | Min 55 °C | Min 65 °C | Min 80 °C |

| Compatible Model MaterialsAll of our materials adhere quite well to most model materials. Feel free to experiment outside of these recommendations. Let us know if you find a new combination 🙂 | ||||

| PLAPlease do not exceed dissolution temperature of 45 ° for PLA | 🟢⚪⚪ | 🟢🟢⚪ | ⚪⚪⚪ | ⚪⚪⚪ |

| PETG, PVB | 🟢🟢🟢 | 🟢🟢🟢 | 🟢⚪⚪ | 🟢⚪⚪ |

| PCTG | 🟢🟢⚪ | 🟢🟢🟢 | 🟢🟢⚪ | 🟢⚪⚪ |

| ABS, ASA, HIPS | 🟢⚪⚪ | 🟢🟢🟢 | 🟢🟢🟢 | 🟢⚪⚪ |

| TPU, TPC | 🟢🟢🟢 | 🟢🟢🟢 | 🟢🟢🟢 | 🟢⚪⚪ |

| PA | 🟢⚪⚪ | 🟢🟢🟢 | 🟢🟢🟢 | 🟢🟢🟢 |

| PET | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢🟢 | 🟢🟢🟢 |

| PC, PC+ABS | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢⚪ | 🟢🟢🟢 |

| PPS | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢⚪ | 🟢🟢⚪ |

| PEEK, PAEK, PEKK | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢⚪ | 🟢🟢⚪ |

| PPCurrently, the adhesion is not good enough for us to approve VXL for PP. Our development team is working flat out on a solution for this. | ⚪⚪⚪ | ⚪⚪⚪ | ⚪⚪⚪ | ⚪⚪⚪ |

For Your Everyday Materials

| VXL 70 | VXL 90 | VXL 111 | VXL 130 | |

| Extruder | 200 - 220 °C | 220 - 240 °C | 230 - 250 °C | 260 - 280 °C |

| BedBed temperature is especially dependent on the used substrate. Use top end temperature on PEI sheet. | 50 - 70°C | 70 - 90 °C | 90 - 110 °C | 100 - 130 °C |

| Build ChamberThese temperatures are slightly below softening point of our materials. The closer you get, the more you need to cool the filament feed path. | Up to 60 °C | Up to 80 °C | Up to 100 °C | Up to 120 °C |

| DissolutionLower temperatures will work, but increase dissolution time. Take care not to damage your model by too much heat! | Min 40 °C | Min 55 °C | Min 65 °C | Min 80 °C |

| Compatible Model MaterialsAll of our materials adhere quite well to most model materials. Feel free to experiment outside of these recommendations. Let us know if you find a new combination 🙂 | ||||

| PLAPlease do not exceed dissolution temperature of 45 ° for PLA | 🟢⚪⚪ | 🟢🟢⚪ | ⚪⚪⚪ | ⚪⚪⚪ |

| PETG, PVB | 🟢🟢🟢 | 🟢🟢🟢 | 🟢⚪⚪ | 🟢⚪⚪ |

| PCTG | 🟢🟢⚪ | 🟢🟢🟢 | 🟢🟢⚪ | 🟢⚪⚪ |

| ABS, ASA, HIPS | 🟢⚪⚪ | 🟢🟢🟢 | 🟢🟢🟢 | 🟢⚪⚪ |

| TPU, TPC | 🟢🟢🟢 | 🟢🟢🟢 | 🟢🟢🟢 | 🟢⚪⚪ |

| PA | 🟢⚪⚪ | 🟢🟢🟢 | 🟢🟢🟢 | 🟢🟢🟢 |

| PET | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢🟢 | 🟢🟢🟢 |

| PC, PC+ABS | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢⚪ | 🟢🟢🟢 |

| PPS | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢⚪ | 🟢🟢⚪ |

| PEEK, PAEK, PEKK | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢⚪ | 🟢🟢⚪ |

| PPCurrently, the adhesion is not good enough for us to approve VXL for PP. Our development team is working flat out on a solution for this. | ⚪⚪⚪ | ⚪⚪⚪ | ⚪⚪⚪ | ⚪⚪⚪ |

to Suit Tough Materials

| VXL 70 | VXL 90 | VXL 111 | VXL 130 | |

| Extruder | 200 - 220 °C | 220 - 240 °C | 230 - 250 °C | 260 - 280 °C |

| BedBed temperature is especially dependent on the used substrate. Use top end temperature on PEI sheet. | 50 - 70°C | 70 - 90 °C | 90 - 110 °C | 100 - 130 °C |

| Build ChamberThese temperatures are slightly below softening point of our materials. The closer you get, the more you need to cool the filament feed path. | Up to 60 °C | Up to 80 °C | Up to 100 °C | Up to 120 °C |

| DissolutionLower temperatures will work, but increase dissolution time. Take care not to damage your model by too much heat! | Min 40 °C | Min 55 °C | Min 65 °C | Min 80 °C |

| Compatible Model MaterialsAll of our materials adhere quite well to most model materials. Feel free to experiment outside of these recommendations. Let us know if you find a new combination 🙂 | ||||

| PLAPlease do not exceed dissolution temperature of 45 ° for PLA | 🟢⚪⚪ | 🟢🟢⚪ | ⚪⚪⚪ | ⚪⚪⚪ |

| PETG, PVB | 🟢🟢🟢 | 🟢🟢🟢 | 🟢⚪⚪ | 🟢⚪⚪ |

| PCTG | 🟢🟢⚪ | 🟢🟢🟢 | 🟢🟢⚪ | 🟢⚪⚪ |

| ABS, ASA, HIPS | 🟢⚪⚪ | 🟢🟢🟢 | 🟢🟢🟢 | 🟢⚪⚪ |

| TPU, TPC | 🟢🟢🟢 | 🟢🟢🟢 | 🟢🟢🟢 | 🟢⚪⚪ |

| PA | 🟢⚪⚪ | 🟢🟢🟢 | 🟢🟢🟢 | 🟢🟢🟢 |

| PET | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢🟢 | 🟢🟢🟢 |

| PC, PC+ABS | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢⚪ | 🟢🟢🟢 |

| PPS | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢⚪ | 🟢🟢⚪ |

| PEEK, PAEK, PEKK | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢⚪ | 🟢🟢⚪ |

| PPCurrently, the adhesion is not good enough for us to approve VXL for PP. Our development team is working flat out on a solution for this. | ⚪⚪⚪ | ⚪⚪⚪ | ⚪⚪⚪ | ⚪⚪⚪ |

for Your Highest Demands

| VXL 70 | VXL 90 | VXL 111 | VXL 130 | |

| Extruder | 200 - 220 °C | 220 - 240 °C | 230 - 250 °C | 260 - 280 °C |

| BedBed temperature is especially dependent on the used substrate. Use top end temperature on PEI sheet. | 50 - 70°C | 70 - 90 °C | 90 - 110 °C | 100 - 130 °C |

| Build ChamberThese temperatures are slightly below softening point of our materials. The closer you get, the more you need to cool the filament feed path. | Up to 60 °C | Up to 80 °C | Up to 100 °C | Up to 120 °C |

| DissolutionLower temperatures will work, but increase dissolution time. Take care not to damage your model by too much heat! | Min 40 °C | Min 55 °C | Min 65 °C | Min 80 °C |

| Compatible Model MaterialsAll of our materials adhere quite well to most model materials. Feel free to experiment outside of these recommendations. Let us know if you find a new combination 🙂 | ||||

| PLAPlease do not exceed dissolution temperature of 45 ° for PLA | 🟢⚪⚪ | 🟢🟢⚪ | ⚪⚪⚪ | ⚪⚪⚪ |

| PETG, PVB | 🟢🟢🟢 | 🟢🟢🟢 | 🟢⚪⚪ | 🟢⚪⚪ |

| PCTG | 🟢🟢⚪ | 🟢🟢🟢 | 🟢🟢⚪ | 🟢⚪⚪ |

| ABS, ASA, HIPS | 🟢⚪⚪ | 🟢🟢🟢 | 🟢🟢🟢 | 🟢⚪⚪ |

| TPU, TPC | 🟢🟢🟢 | 🟢🟢🟢 | 🟢🟢🟢 | 🟢⚪⚪ |

| PA | 🟢⚪⚪ | 🟢🟢🟢 | 🟢🟢🟢 | 🟢🟢🟢 |

| PET | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢🟢 | 🟢🟢🟢 |

| PC, PC+ABS | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢⚪ | 🟢🟢🟢 |

| PPS | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢⚪ | 🟢🟢⚪ |

| PEEK, PAEK, PEKK | 🟢⚪⚪ | 🟢⚪⚪ | 🟢🟢⚪ | 🟢🟢⚪ |

| PPCurrently, the adhesion is not good enough for us to approve VXL for PP. Our development team is working flat out on a solution for this. | ⚪⚪⚪ | ⚪⚪⚪ | ⚪⚪⚪ | ⚪⚪⚪ |