Table of content

Using support materials that require a solvent raises a vital question: How safe are these solvents? How safe is VXL-EX?

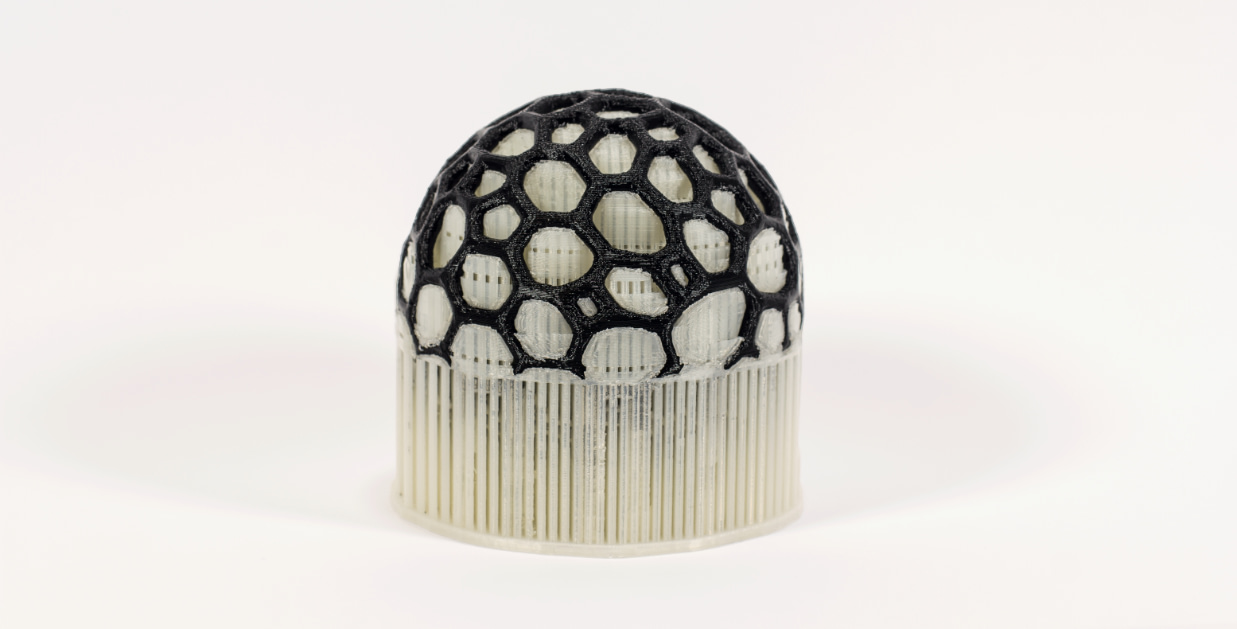

Dissolvable support materials do an admirable job when it comes to creating a wide range of geometries with our FFF 3D printers. Nonetheless, dissolving these materials is a task that demands specific consideration.

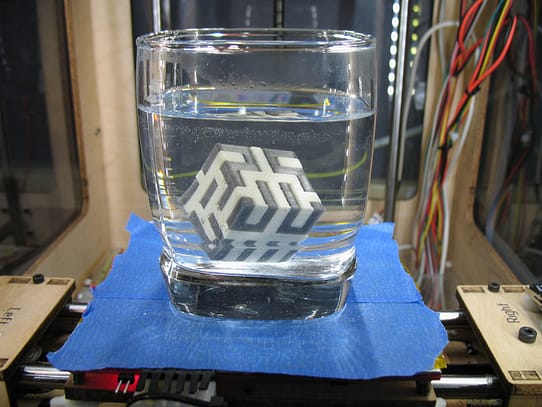

We frequently come across videos and images showcasing support structures effortlessly dissolving in a pristine glass, within a clean workspace. The process appears straightforward, neat, and flawless.

However, the actual process of dissolving supports is often far less tidy than these pictures, videos, and promotional material suggest. Without adequate temperature control and agitation, dissolving PVA (or PVOH) takes significantly more time. Moreover, larger parts require a container more spacious than a mere glass.

Here’s a snapshot of our support removal area before we transitioned to professional support removal stations. Despite PVA supports being water-soluble, the workspace hardly resembles the gleaming image often associated with PVA.

So, this raises the pertinent question: If the support material removal area can get so messy, how can we guarantee our safety? This question becomes especially relevant when you’re dealing with support materials that necessitate a solvent beyond pure water.

Instances of these material-solvent pairings include HIPS + Limonene, VXL + VXL-EX, and, potentially, support materials requiring NaOH (caustic soda) for dissolution.

The paramount question is, how safe are these material-solvent combinations?

Why use solvents at all?

Wait a minute. If we have to think about safety while using solvents, why not simply opt for water-soluble support materials like PVA, PVOH, or others and be done with it? Sure, the workspace might get a little messy, but at least we can ensure our safety.

However, water-soluble support materials come with significant downsides in the realm of 3D printing.

Disadvantage 1:

Regarding temperature resistance, materials like PVA and BVOH tend to degrade rapidly within the nozzle, leading to occasional clogs in the print head. This is the primary reason people lodge complaints against these materials.

Disadvantage 2:

When discussing reliability, all water-soluble filaments share another drawback. They have a penchant for rapidly absorbing moisture from their surroundings. Consequently, you must store water-soluble materials in dry conditions or even pre-dry them before use.

Disadvantage 3:

Yet another pitfall of water-soluble supports lies in their incompatibility with a broad array of model materials. For instance, PVA doesn’t adhere well to most model materials, whereas VXL forms stronger bonds with PC, ABS, TPU, PETC, and other filaments. Additionally, PVA’s low melting point renders it ineffective with high-temperature materials such as PEEK. To print PEEK, you must opt for VXL-130.

Disadvantage 4:

Ultimately, water-soluble structures tend to collapse into a sticky mass when submerged in water. This results in slower dissolution. Furthermore, water has limited capacity to dissolve polymers. Therefore, to expedite the process, adding a solvent can prove highly beneficial for efficiently removing your supports.

So, in summary, using support materials that necessitate a solvent other than plain water can offer substantial benefits over water-soluble supports: enhanced reliability in printing, improved compatibility with model materials, and faster dissolution.

HIPS and Limonene

HIPS stands as one of the original rivals to PVA within the open 3D printing community.

Dr. Andrei Neboian

High-Impact Polystyrene (HIPS) is an economical thermoplastic material frequently employed in the production of consumer goods and toys. It shares similarities with ABS but exhibits a softer and less robust nature. Yet, the advantage of HIPS is its strong compatibility with other styrene-based materials like ABS, making it a valuable support material.

However, have you ever tried squeezing an orange peel over an open flame? The small droplets from the peel will ignite. The reason behind this phenomenon lies in the fact that Limonene present within the peel is a highly flammable substance. Therefore, working with Limonene in your support removal area entails the risk of fire. It demands careful handling.

Moreover, the process of dissolving HIPS with Limonene may yield hazardous byproducts. Limonene also has the potential to irritate the skin. Consequently, many countries have instituted regulations governing the disposal of Limonene, making it illegal to simply dispose of it down the drain.

All these factors collectively render HIPS + Limonene a relatively unsafe combination in your 3D printing arsenal.

PLA and Caustic Soda (NaOH)

We conducted several experiments on this in a laboratory setting, but we strongly discourage attempting this at home.

In our experiments, we 3D printed a part using ABS and utilized PLA as the support material. To eliminate the PLA supports, we immersed the printed object in a highly concentrated solution of sodium hydroxide (NaOH). The solution swiftly disintegrated all the PLA supports, leaving behind only the ABS component within a few hours.

Although this approach yielded favorable results in our experimental trials, we emphatically advise against employing it for routine use.

Sodium hydroxide (NaOH) is an extraordinarily hazardous chemical. It may be colorless and odorless, but it is highly corrosive, caustic, and thus harmful. The extent of harm depends on the quantity, duration of exposure, and concentration. It can cause burns to the eyes, skin, and mucous membranes and lead to temporary hair loss.

When one accidentally spills a concentrated acid on their skin, the immediate response is intense burning pain. In such a situation, one would rush to the nearest sink and attempt to flush the chemical off their skin. However, caustic soda (NaOH) behaves deceptively. Upon contact with the skin, it does not elicit the same pain response. Unbeknownst to the individual, the substance silently penetrates the flesh, causing severe, slow-healing, and potentially infected burns.

Some manufacturers still employ NaOH for support removal. Therefore, extreme caution is mandatory when dealing with support removal using NaOH.

VXL and VXL-EX Washing Powder

The latest, and arguably the most dependable soluble support material available, is VXL. It dissolves in a solution of water and VXL-EX, a specially formulated detergent for VXL.

Here’s the good news upfront: VXL-EX is non-corrosive and safe to use, unlike the solvents mentioned earlier. When mixed with water, it creates a mildly alkaline solution for dissolving supports that are 3D printed using VXL filament.

We asked the chemical engineer behind VXL-EX about its composition, and he didn’t hesitate to respond: “The solvent is similar to the detergent we all use for our laundry.”

Several critical factors influence the speed at which VXL-EX dissolves the VXL support material:

- Temperature: The water temperature dictates the speed of the removal process. For instance, using VXL EX in a heated bath will yield faster results than using lukewarm water. Recommended dissolving temperatures depend on the type of VXL and model material you use, ranging from 40°C to 90°C (100°F to 200°F).

- Agitation: Stirring the solvent around the 3D printed part and its supports will accelerate the dissolving process. Think of dissolving a spoonful of sugar in a cup of tea: the faster you stir, the quicker the sugar dissolves.

- Quantity of Supports: The general rule is a 1:1 ratio for VXL EX. This means that for every 100 g of VXL, you will need 100 g of VXL-EX to dissolve it. To conserve material, we often use a handy trick: we remove large chunks of easily accessible VXL supports before immersing the part in a bath. Once the larger support structures are trimmed away, VXL-EX dissolves the remaining supports much more rapidly.

- Support Geometry: The more complex and intricate the geometry, the longer it takes to dissolve the supports. This is logical since the liquid flows more slowly in hard-to-reach areas and deep cavities. In such cases, increasing solvent agitation proves highly beneficial.

You can learn 5 methods on how to effectively dissolve support structures in this article.

In contrast to Limonene, VXL-EX offers a safer solvent option due to its low corrosive properties. However, this doesn’t mean that users should neglect standard safety practices during post-processing when working with any solvent. It is still recommended to wear appropriate protective gear that safeguards the skin, eyes, and respiratory system when handling VXL-EX.

VXL-EX vs. other Solvents

Limonene is flammable, known to react irritably with the skin, release potent fumes, and cause irritation if it comes in contact with the eyes. VXL-EX would also cause irritation if you rub it into your eye, so always use protective gloves and eyeglasses to be on the safe side. But, on the other hand, VXL-EX is not flammable and does not release toxic fumes.

More importantly, VXL-EX is non-caustic, making it much safer than caustic soda (NaOH).

So if you can handle a conventional laundry detergent, you will be able to handle VXL-EX to dissolve your VXL supports too.

The higher efficiency of the VXL + VXL-EX sets it further apart from other combinations. Limonene provides inconsistent results and can eat through and bleach out filament colors when used. But VXL-EX is a low-corrosive removal powder that does not reduce the quality of the processed 3D print.

So what is the answer on our question?

Does a safe, reliable washing powder for removing support materials exist? The answer is yes.

VXL-EX provides 3D printing enthusiasts and professionals with a safe, reliable washing powder for removing support materials from VXL. The washing powder is mild and can be safely stored within tight containers for recurring post-processing activities, thereby saving cost.

Learn more about the washing powder VXL-EX, our support materials VXL, and our support removal stations.