Comprehensive guide to 5 low-cost dual-material FFF printing technologies in 2021/2022

This story was originally published on www.fabbaloo.com (see Part 1 and Part 2).

“I don’t care about multi-color, I just want soluble supports,” writes a 3D printer user in a forum on dual-material 3D printing.

Sure, a model of a four-colored amazon rainforest frog would look great in your 3D printed collection. But enough users would agree that the true potential of dual-head printers lies in their ability to print soluble supports rather than a palette of colors.

A quick search on Google reveals dozens of soluble support filaments on the market. Most of them are based on well-known water-soluble polymers PVA and BVOH. But there are also new contestants coming out such as VXL from Xioneer that provide superior performance to PVA.

But printing a support-material combination is not the same as printing two colors of the same filament. So, which dual extrusion 3D printer is up to the task?

In general, multi-material FFF technologies can be classified into five categories – each with its own pros and contras when it comes to printing soluble supports.

Depending on how often you print, what support material you use, and how much you are willing to invest, you might even find the perfect match for your needs.

The good news: you can get a decent 3D printer in any of these categories for under $ 1,000. So read on.

1. Mixer 3D Printers: Lowest Price-Tag But Probably Not the Best Choice for PVA

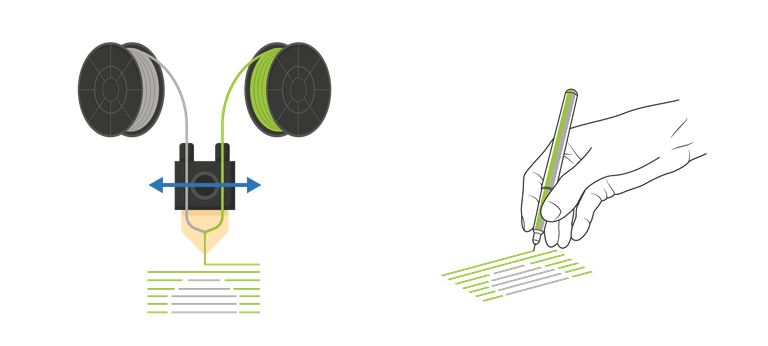

In 2014, the legendary 3D printer component manufacturer E3D came out with its “Cyclops” hot-end. The name says it all: It is a hot-end with two inlets, but only one outlet: the “eye.”

This mystical creature takes two filaments in, melts them inside, and extrudes a single strand of mixed material. It’s great for mixing colors and creating stunning color gradients in your parts using just two filaments.

But can it also print supports?

The mixer hot-end acts as a Y-splitter – letting you extrude either support or model material from a single nozzle – without mixing them together. So yes, it can print supports too.

3D printers with a mixer hot-end like the Geeetech A10M sell from USD 230. This price tag is really hard to beat when it comes to something as sophisticated as dual-material 3D printing.

Nozzle calibration on these machines is straightforward because they use only one nozzle. No need to fiddle with extruder offsets, which are notorious in systems with two separate nozzles. So with a device like A10M you could start churning your complex models with supports soon after unboxing.

But before you grab your credit card to order an A10M, you might want to keep learning about some of the drawbacks.

Mixer hot-ends require you to print a purge tower with every print job. It is a way to clean the nozzle before switching materials and avoid material bleed in your parts.

But getting the right amount to purge can be tricky. Purge too much and you needlessly waste precious filament. Purge too little, and the residues of support filament will contaminate your model affecting part stability and surface quality in the end.

But one way or another: mixer hot-ends will always produce waste.

Besides, using PVA with a mixer hot-end is a challenge on its own.

PVA and similar water-soluble materials are very sensitive to heat. If you leave them lingering for too long in a hot nozzle, they will degrade and turn into a crusty mess – clogging your extruder.

So, with mixer hot-ends, you want to keep PVA flowing through your nozzle as much as possible. This means shorten time window to print model materials. In practice, you will print only smaller models to avoid a clogged nozzle when using a mixer hot-end.

One trick is to use more temperature-stable support material such as VXL from Xioneer. But if you absolutely need to stick to PVA, the only remedy seems to use two separate nozzles – each with its own temperature control.

2. Traditional Dual-Extruders: Work With PVA But Are a Challenge to Calibrate

What’s the benefit of using two nozzles (for model and support materials respectively) versus a single alá “Cyclops” nozzle?

Using two nozzles lets you cool PVA inside your support nozzle while you print your model material with another nozzle. This helps prevent PVA from overheating and eventually clogging your extruder.

But this requires some tweaking to get it right.

However, PVA will need at least a 20°C-50°C temperature drop to keep the material from degrading too quickly. This leads to long heat-up times for every layer, adding to hours of unproductive time throughout the entire print job.

One solution is to use a temperature-stable support material such as VXL instead. The material does not degrade as quickly as PVA inside a hot-end saving you the need to cool down your support nozzles.

The two low-cost dual-printhead 3d printer models often found in reviews are the X-Pro from Qidi Technology and the Bibo Dual Extruder 3D Printer. These printers seem to be popular due to their low prices of $482 and $650 respectively.

A decent 3D printer model comes from Prusa with its I3 MK3S+ together with the dual head upgrade. This kit would burden your wallet with around 890 euros. However, the reputation of Prusa and its supportive community, this investment may pay itself off quickly.

But despite their advantages over mixer hot-ends, dual-printhead models do not always sell well. I once asked one of our resellers why.

The problem wasn’t the higher price. It was the complexity of getting these systems calibrated. This reseller required its users to undergo rigorous mandatory training to learn how to use dual-head machines (probably to save hours of support calls later on).

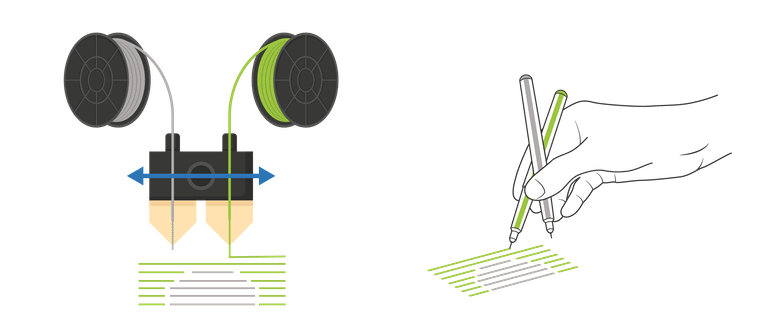

Imagine holding two pens in your hand and trying to write something with both of them at the same time. One of them will always try to lift up, while the other will be pushing too hard against the paper. It’s really tricky.

The same problem happens when printing with two nozzles mounted on a single print-head. If one is too low, it may kick your part off the build plate. If it is too far, the layers will not bond well.

So calibrating the height of two nozzles in a sub-millimeter range will take time and experience to get it right before every print job.

Actually, this problem was one of the reasons 3d printing companies came up with another solution: place both nozzles on separate print-heads: each with its own temperature and motion control.

3. IDEX: Most Likely Your Top Choice For Support Materials

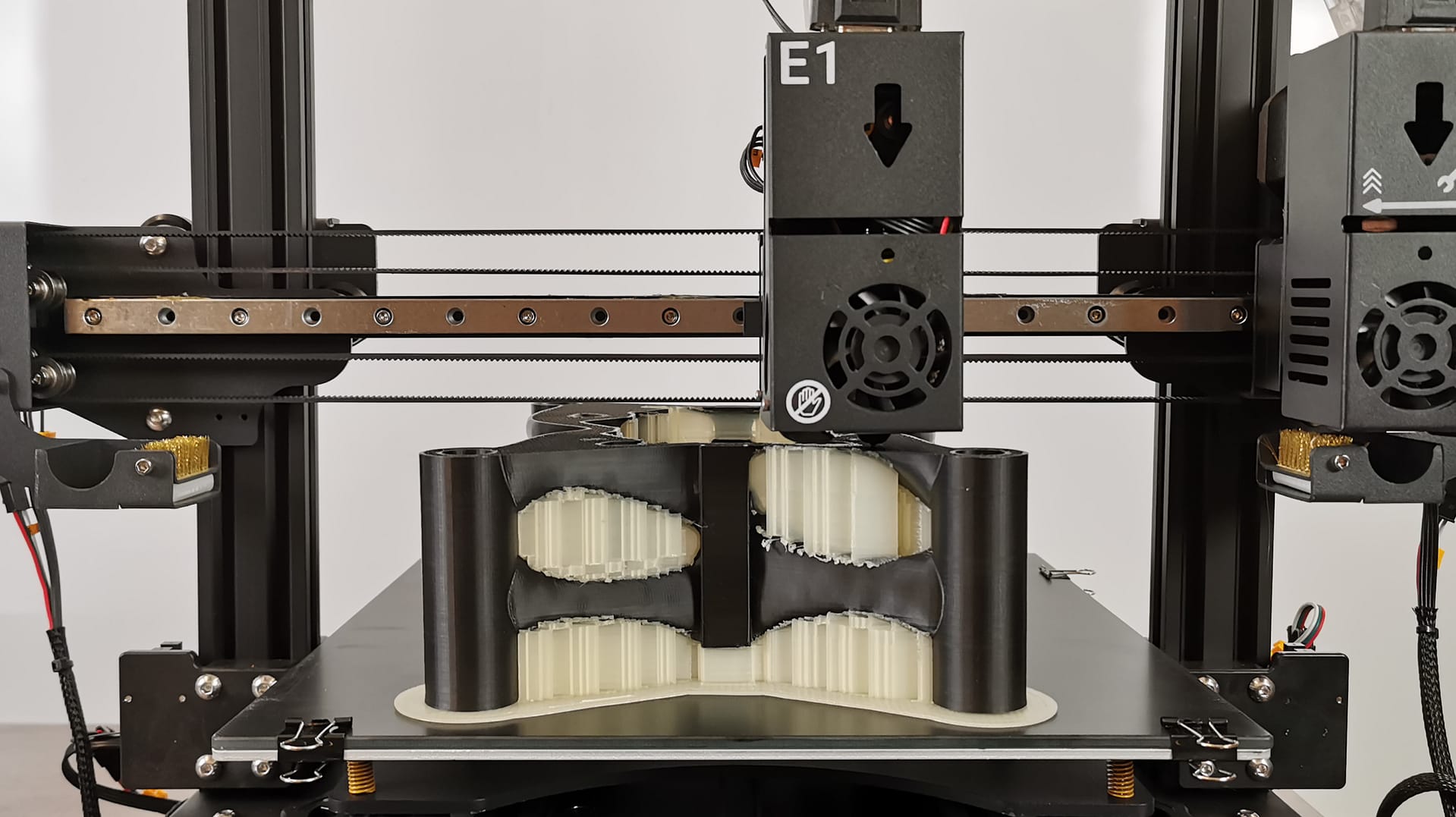

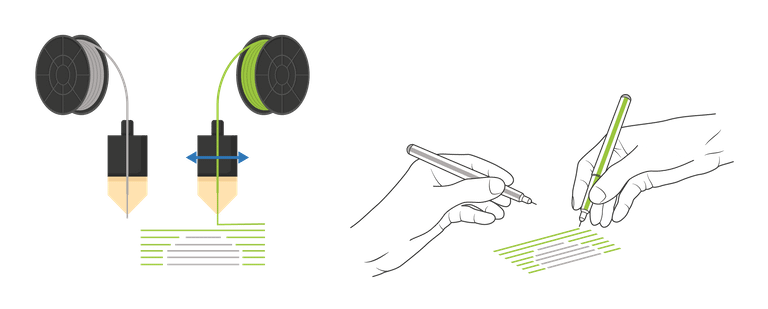

IDEX stands for an independent extruder 3d printer. These systems use two extruders that alternate in the printing process.

So instead of trying to hold two pens in one hand, you take one pen in each hand – and write with each of them individually. Now, most of us aren’t ambidextrous (able to write with left and right hand equally well) – the machines do a great job printing with a pair of independent print-heads.

The first benefit of two independent nozzles: they are typically easier to calibrate than two nozzles mounted on a single print-head.

Another benefit of IDEX systems: they park unused nozzles outside of the build area, where they can leak material without oozing over your part.

Oozing is indeed a big issue not only in multicolor 3D printing but in printing model-support combinations. The smeared support may leave blemishes and holes inside your model undermining its aesthetics and surface finish.

So using IDEX 3D printers typically results in more reliable printing, prevents scraping of nozzles over the parts, and creates smoother surfaces. Such systems come very close to being the top choice for printing with support materials.

One of the lowest cost IDEX machines is the Tenlog Hands 2 Pro which retails at $430. The machine encompasses an impressive build volume of 235 x 235 x 250 mm. If you need to print larger parts, Tenlog offers its TL-D3 Pro with 310 x 310 x 350 mm build volume with a price tag of $ 560.

Another popular IDEX model appearing in 2021 reviews is the Creator Pro 2 from FlashForge. It is available for USD 700 and comes with a number of useful features such as an enclosed build-area to reduce the warping of parts. The Creator Pro 2 has a build space of 200 x 148 x 150 mm.

When it comes to printing support materials (VXL or PVA), machines with independent extruders offer the best price-performance ratio in my opinion.

4. Tool Changers: Smooth Parts But Comes With a High Price-Tag

Tool changers are nothing new in the world of CNC machining. But in 3D printing, they are considered an exotic species. Although priced above a thousand dollars, it would be unfair to leave them out of this review.

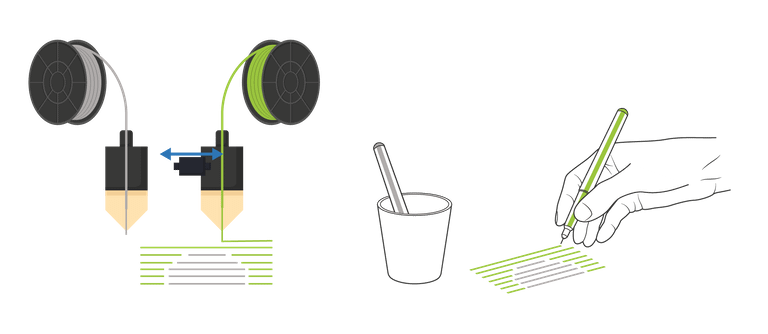

In our pen and paper example, tool changing is the equivalent of picking a pen from a cup whenever you need it. When you are done writing with one pen, drop it back into a cup, and simply pick another one. In fact, this is what we (humans) naturally do when we want to use two pens.

For a machine, this approach has a few benefits.

A machine with a tool-changer only needs a single set of motors. So overall, these systems typically exhibit fewer moving masses, letting you reach smoother surfaces on your parts. This is clearly an advantage when printing intricate models with lots of supports.

But this solution is generally the most expensive choice. This is bad news if you are looking for a 3d printer with a tool-changer under one thousand bucks: we didn’t find any as of this day.

The option that comes to mind is to build a tool-changing dual extruder 3D printer yourself. You can get a head-start with a $ 2,105 (excl. VAT) Tool Changer & Motion System Bundle from E3D that provides all the mechanics you need to create such a beast.

5. Filament Switchers: Great for PVA But Produce Waste

The Canadian company Mosaic Manufacturing came up with a multi-material 3D printing solution that is truly out of the box.

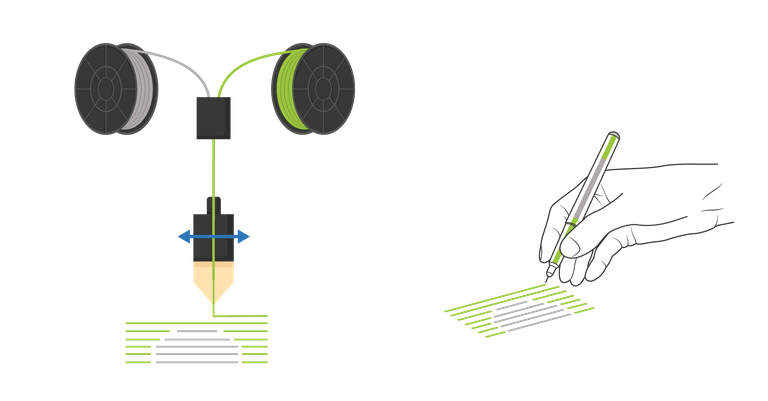

Mosaic Palette 3 is a device that cuts different filaments and welds them together in a single multi-material filament strand. Depending on the amount of model and support material for each layer, the device will precisely chop the filaments in lengths as needed – and deliver a welded strand to your 3D printer.

The device is an add-on. This means a great deal if you already own a single-extruder 3d printer. No need to buy a new dual-extruder machine and calibrate its two nozzles. You can keep using your single-extruder 3D printer and fit the Palette post factum.

Agreed, a price tag of $599 is more than double what you pay for a Geeetech A10M, but the Palette 3 seems to offer a unique benefit when it comes to printing with support materials.

Switching filament before the melt-zone on Palette makes sure that PVA is delivered to the nozzle only when it is needed. So PVA does not have a chance to linger in a hot nozzle eventually clogging it. This should drastically improve printing reliability.

Another – less expensive option – is the Prusa’s MMU2S Upgrade that retails for USD 300, but it was designed specifically for upgrading Prusa printers in mind.

However, both products seem to have a major drawback: they produce lots of waste when switching from one material to another.

On the mosaic website, the manufacturer states: “In order to create clean, high-quality multi-color/material prints, Palette uses a Transition Tower. This allows your extruder to purge the filament in between transitions, creating precise breaks in your model. Without these towers, the quality of the print would be reduced due to filament bleed and other print issues.”

They recommend purging 130mm of filament for its transition tower on each layer. Now, for a 1000-layer object, this amounts to 130 meters of wasted material or about a half of a 750g spool! This may not seem like a big deal when using cheap PLA or ABS. But you may consider accounting for so much waste when using expensive support materials such as PVA and VXL.

Mosaic and Prusa do provide tips and tricks on how to reduce material waste. For example, printing multiple objects at once, or using your model infill as a purge/transition area. But clearly, the material waste remains one of the key issues of filament switchers.

Summary

Printing model and support is no longer a luxury of high-end expensive FFF machines. You can get a decent dual-material system well under $1,000.

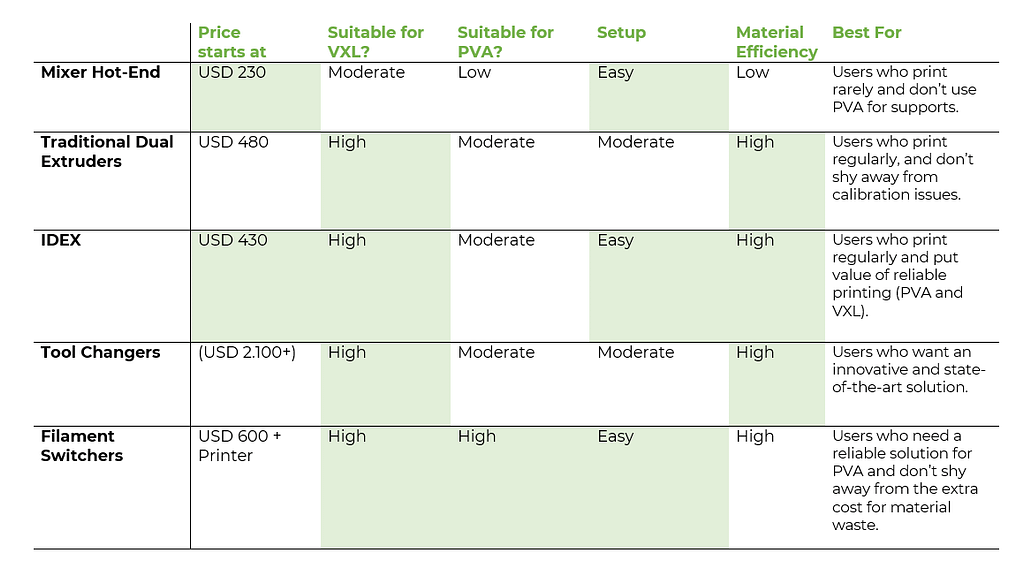

The table below gives a summary of the low-cost options available on the market today.

If you are aiming for the lowest price and plan to use VXL instead of PVA as your support material, then you may seriously consider getting the Geeetech A10M. The device comes with the added benefit of simpler calibration due to a single-nozzle setup.

But if you look for a more reliable printing experience with PVA and less material waste, you should be looking into an IDEX machine like the TenLog Hands 2 Pro or the Creator Pro 2 from FlashForge. The nozzle calibration is a bit trickier than on A10M, but not as challenging as on traditional dual-nozzle machines.

For the highest reliability when printing with PVA, and if you don’t mind the notable material waste, you might find a filament switcher like the Mosaic Palette 3 or Prusa’s MMU2S as an attractive option. The system gives PVA the least chances to burn and clog in your nozzle. The device is an add-on you can fit onto an existing single-head 3d printer.