The statistics are in: 4 out of every 10 projects in FFF 3D printing are bound to fail. However, all is not lost.

In-depth analysis shows that the common challenges you face such as stringy prints, uneven surface texture, blocked nozzles, etc. are due to preventable causation factors such as “wet” filament spools.

What is a “wet” filament, you ask?

The short answer is: thermoplastic filament is hygroscopic, which means it absorbs moisture from the atmosphere. The longer answer takes into consideration the type of filament you purchase, how the spool is packaged, and more importantly, how you store your filament. This post will discuss:

- The implications of utilizing “wet” filament for 3D printing

- Filament drying processes and their peculiar characteristics

- The importance of proper filament storage for developing industrial-grade 3D prints.

Wet Filament and Its Associated 3D Printing Challenges

A cursory Google search on wet filament brings up diverse links including a popular Reddit post that describes the fallout from moist spools as a myth. Ignore this and scroll further down and you’ll find first-hand reports highlighting that your wet filament is most likely responsible for:

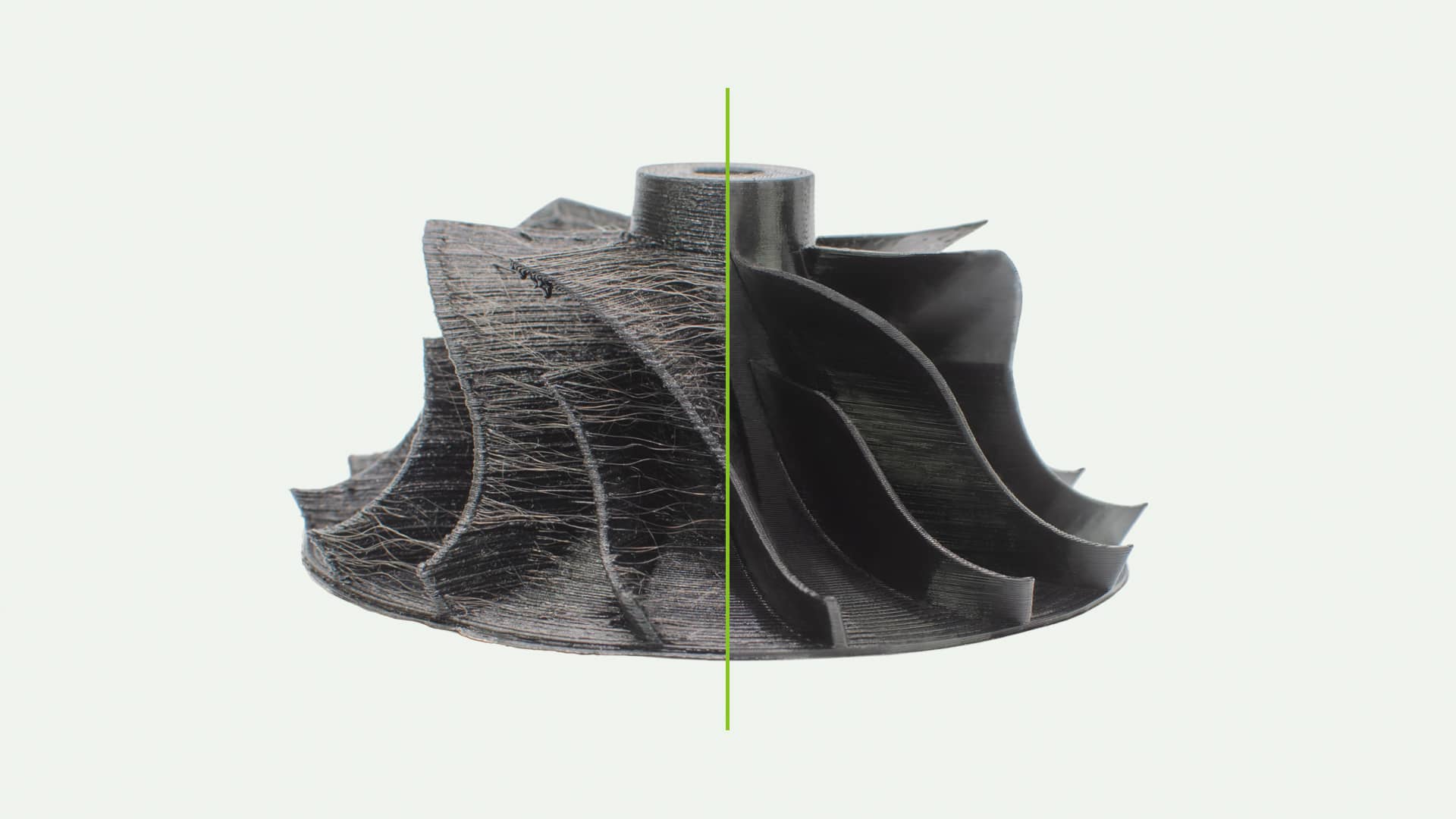

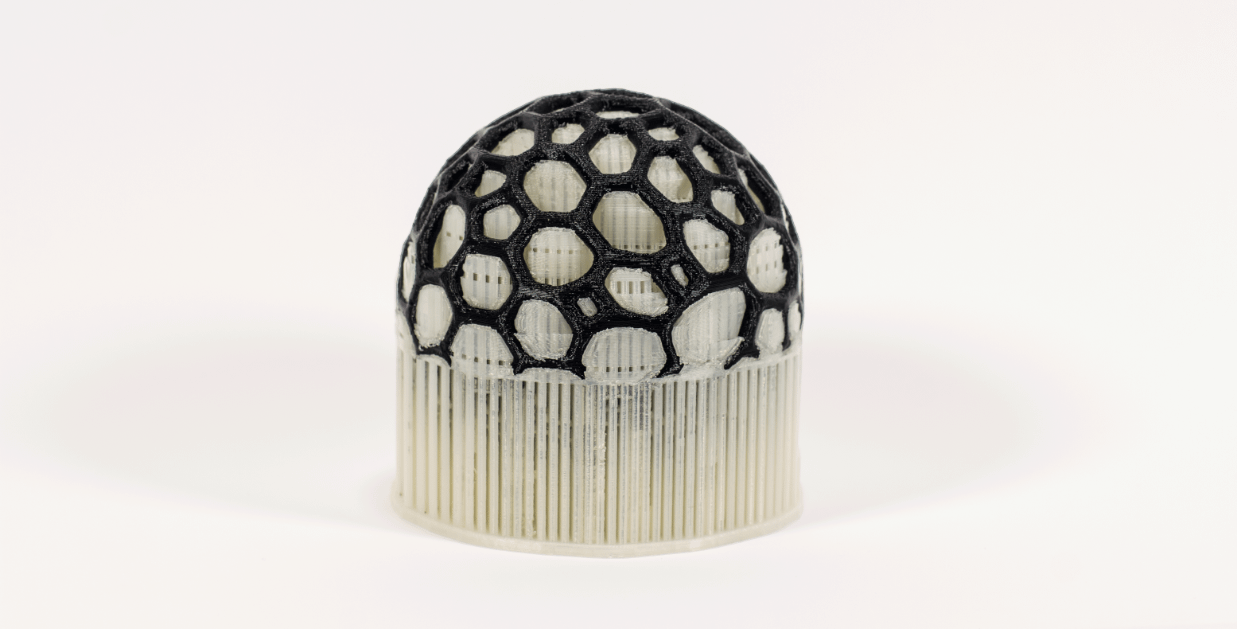

- Stringing: This refers to the hairy strings of plastic trailing your finished 3D print that no amount of post-processing can correct.

- Uneven Surface Texture: Your FFF 3D printer extrudes molten filament in layers and wet filament affects the uniformity of extruded layers. Lack of uniformity leads to the uneven surfaces you sometimes struggle with.

- Clogged Extrusion Nozzle: A nozzle that refuses to extrude filament means it must be clogged or poorly set. If you have cleaned the nozzle, reset your printing platform and it still refuses to extrude filament, the most likely culprit is moisturized filament.

- Popping Sounds: The average 3D printer produces mechanical noises when functioning but when popping sounds are heard followed by intermittent extrusions or stingy extrusions; this is a sign to stop printing. The sound is likely caused by wet filament.

To Dry or Not to Dry Filament

Delving into the diverse drying process or whether drying filament works before outlining the processes to pinpoint wet filament is reductive. So, how can one tell if the filament is wet? Thankfully, some tell-tale signs exist that can help you diagnose the state of your spools.

First, it’s worth mentioning that your eyes are not efficient tools for differentiating between the dry filament and moist filament inside vacuumed packages. Except you can find beads of moisture on the surface of your spool package, you can’t tell if it has absorbed moisture without extruding some filament.

Thus, the best method is extruding some filament to note signs such as popping sounds, hissing noises, air bubbles, or to see if steam comes from the nozzle. Any of these signs are indicative of wet filament. So if you choose to continue 3D printing with wet material, then you are likely to increase the failure rate from 40% to around 60%.

Thus, drying and keeping filament dry is a definite recommendation for increased 3D printing success.

Traditional Filament Drying Methods

Oven Drying

DIYers and professional 3D printers still utilize oven baking to get the moisture out of ABS and PLA filament. The drying process is similar to baking your favorite thanksgiving turkey. Just place your filament spool inside an oven and set it at the right temperature:

- 104 to 113°F (40 – 45 °C) for PLA

- 176°F (80°C) for ABS

- 176°F (80°C) for PA/Nylon

You are expected to maintain this temperature to ensure not to melt the plastic filament or the spool. Maintaining temperatures while drying can be difficult in situations where your oven can’t keep set temperatures. The built-in oven thermometer is often not precise enough to avoid damaging temperature fluctuations. Thus, the drying process involves a lot of checks with an additional thermometer to ensure you do not ruin your filament.

Food Dehydrators

Dehydrators preserve food by applying a constant warming temperature to limit the natural oxidation process that causes spoilage. The constant warming process is applied to drying filament for 3D printing purposes. Unlike the average oven, the average food dehydrator can keep a temperature but they operate at lower temperatures and must be kept running most of the time in order to keep your filament dry.

Dedicated Filament Dryers

Before choosing to throw plastic into your oven or reconvert food dehydrators into filament drying devices, the option of utilizing a filament dryer exists. A filament dryer is an appliance that is easy to use. You put the wet filament into the dryer, pick specified settings and wait for a couple of hours, as specified in the manual, and you get dry filament. Filament dryers are the recommended tools built to remove moisture from thermoplastic.

Advanced filament dryers include a sorption unit besides a heater. These units absorb humidity making the air inside the dryer very dry. If you have ever been in a desert, this is what the air inside such a dryer feels like: dry and hot. Compare it to the air in a tropical rainforest: it’s still hot, but not as dry. We know that things will dry much quicker in a desert than in the rainforest despite similar air temperatures.

So, using dryers with a sorption unit allows you to dry filaments more effectively. In the above list, only the third option has this possibility.

Don’t Wait Too Long to Dry

So it may seem that drying your filament is not a big deal. Shove a spool inside an oven and the filament is as good as new in a few hours. But unfortunately, polymer chemistry does not make it that simple.

As polymers absorb humidity, water molecules slowly enter the space between the molecular polymer chains of your filament. As this happens, water breaks these long chains into smaller chains. This effect is called hydrolysis. As polymer chains become shorter, they become weaker undermining the overall mechanical strength of the material. Unfortunately, you will not notice this effect with the naked eye: the damaged filament will look and feel the same. But the parts 3D printed with a hydrolyzed material will be weak and brittle.

So in the end, some filaments like Nylon (PA) can become so saturated with humidity, that no dryer will rescue them. Hydrolysis will take its hold no matter the drying method. You can recognize excessive hydrolysis by trying to break the filament after drying: it will be extremely brittle. For these materials, which were lying around for far too long, the only way is into your trash can.

To prevent unnecessary material waste and failed prints, keep your filaments stored in a dry environment at all times.

Drying and Storing Spools Using Filament Cabinets

We’ve already established the fact that wet filament equals failed 3D printing projects. What hasn’t been established is that drying and restoring your filament in inadequate storage spaces results in another drying session. Filament cabinets double as professional drying devices and comfortable storage spaces for your spools.

Industrial-grade filament cabinets are capable of more than drying and storage. They also provide features such as filament feed-through, filament outlets for PTFE tubes, and adjustable drying settings. An example is the DryBox EZ that dries, stores, and feeds your FFF 3D printer with a continuous loop of humidity-optimized filament.

Filament cabinets are built for DIYers, hobbyists, and professionals interested in eliminating moisture and properly storing filament to 3D print high-precision models. If you intend to store large quantities of spools for recurring projects, then a filament cabinet is the drying option that guarantees improved 3D printing success rates. The table below compares diverse drying processes and the associated pros and cons.

| Drying/Storage Technique | Drying/Storage Process | Pros | Cons |

| Oven Drying | Place filament into a preheated oven and wait for it to dry. | Dries filament quickly and affordably, and is therefore accessible to anyone with a kitchen. | Requires monitoring. Excessive heat can damage the produce volatile organic compounds. Gas ovens come with safety regulations and issues. |

| Food Dehydrators | Place filament into the dehydrator and patiently wait for it to dry. | Affordable as a home utensil and easily accessible to those who dry fruits. | The slow drying process. The filament goes where your food should. However, some vendors do offer repurposed food dehydrators as Filament Dryers. |

| Filament Containers | Place filament into a spool-size box during printing. | An affordable device built solely for reducing exposure of filament to the surrounding air. | No drying option. Besides, storage space is typically limited to one spool only. So these devices are mostly used for a spool you currently print with, but not to store all your other open spools. |

| Filament Drying Cabinets | Place filament into the dryer and setting recommended drying parameters. | Equipped with settings for drying different filament types, has the storage capacity to ensure your filament is constantly dry. Some filament dryers come with sorption units, which boost drying efficiency. | Relatively more expensive but ensures safety, efficiency, and proper storage of your filaments. |

Xioneer DryBox EZ

Our Xioneer DryBox EZ is a filament cabinet that brings all the benefits associated with properly storing thermoplastic spools in one simple-to-use product. Xioneer DryBox EZ is an example of a turnkey cabinet with adjustable drying settings, filament feed-through, and compatibility with all filament types. The Xioneer DryBox EZ also provides 3D printing enthusiasts and professionals with the choice of storing approximately 5Kg of filament.

Conclusion

Choosing to dry your wet filament improves the overall 3D printing process by eliminating the common problems associated with moisture. Utilizing a filament cabinet removes moisture and keeps your spools in pristine condition for every project.